Marine paints from FUXI Coatings are the paints that are painted on various parts of the ship to extend its service life and meet the special requirements.

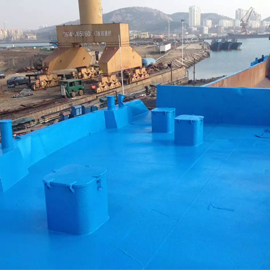

Marine paints are a series of paints such as ship primer, ship bottom anti-rust paint, antifouling paint, boot topping paint, hull and superstructure paint, various cabin paints, ballast water tank paint, oil tank paint, drinking water tank paint and dry cargo hold paint.

Workshop primers for marine include phenolic modified phosphate primer, epoxy zinc-rich primer, and zinc free primer.

Anti-rust primers include zinc phosphate anti-rust paint, zinc chromate yellow anti-rust paint, red lead anti-rust paint, and other anti-rust paints.

The ship bottom paints are the paints used for the underwater parts of the ship, including ship bottom antirust paint and antifouling paint.

Excellent Protection: Our paint for ships offers superior adhesion, water resistance, chemical resistance, and abrasion resistance. With outstanding anti-corrosion performance, this coating ensures reliable protection even under the harshest marine and chemical environments.

Long-Lasting Durability: Depending on the application environment, certain types of marine paint can provide anti-corrosion protection for 10–15 years in marine or chemical atmospheres, and more than 5 years even in acid, alkali, salt, or solvent media.

High-Build and Cost-Effective: Designed as high-build coatings, our marine paint types deliver excellent film quality at a reasonable price, making them a practical choice for large-scale shipbuilding and maintenance.

Strong Adhesion: Marine paint forms a firm bond between the coating and the substrate, ensuring long-term durability and reduced maintenance needs.

Easy Application: Our paint for ship products are engineered for efficient, convenient application, helping shipyards and operators save time and costs.

Normal Temperature Drying: The size of ships makes heating impractical, so marine paint types should be able to dry naturally at normal temperature.

Airless Spraying Compatibility: Given the large construction areas, types of marine paint must be suitable for high-pressure airless spraying to ensure efficient and uniform application.

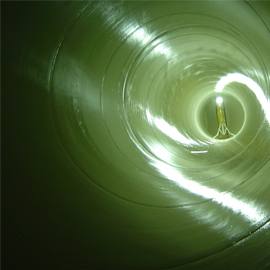

High-Build Coating: For hard-to-reach areas, coatings need to achieve the required film thickness in a single layer, making high-build paint for ship applications essential.

Underwater Protection: Hull sections below the boot topping require China coatings with excellent electric potential resistance and alkali resistance, as oil-based or modified paints are prone to saponification and unsuitable for underwater use.

Fire Safety Standards: For the engine room and superstructure, coatings must be flame-retardant and produce minimal smoke if ignited. Therefore, nitrocellulose paint and chlorinated rubber paint are not suitable for cabin decoration.