Marine paints are the paints that are painted on various parts of the ship to extend its service life and meet the special requirements.

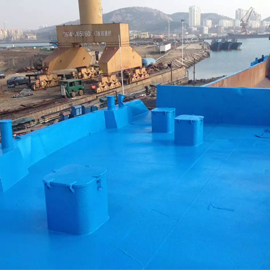

Marine paints are a series of paints such as ship primer, ship bottom anti-rust paint, antifouling paint, boot topping paint, hull and superstructure paint, various cabin paints, ballast water tank paint, oil tank paint, drinking water tank paint and dry cargo hold paint.

Workshop primers for marine include phenolic modified phosphate primer, epoxy zinc-rich primer, and zinc free primer.

Anti-rust primers include zinc phosphate anti-rust paint, zinc chromate yellow anti-rust paint, red lead anti-rust paint, and other anti-rust paints.

The ship bottom paints are the paints used for the underwater parts of the ship, including ship bottom antirust paint and antifouling paint.

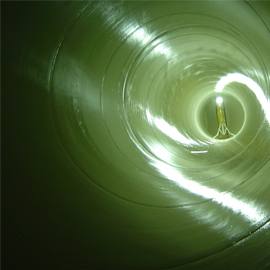

It has good adhesion, good water resistance, chemical resistance and abrasion resistance, and excellent anti-corrosion performance. Paint for ships can be used under harsh conditions and has a long-lasting anti-corrosion life generally as long as 10 or 15 years in the chemical atmosphere and marine environment. It can be used for more than 5 years even in acid, alkali, salt and solvent media.

High-build coating film, good quality and reasonable price are important characters of marine anti-corrosive paint.

Marine paint has a strong adhesion between the coating and the substrate.

Ship paint is efficient and convenient for coating application.

The size of the ship determines that marine paint must be able to dry at normal temperature. Paint that needs to be heated and dried is not suitable for marine paint.

The construction area of marine paint is large, so the paint should be suitable for high-pressure airless spraying applications.

It is difficult to paint certain areas of ships, so it is hoped that a high build coating film thickness can be achieved in one coating, so high build paint is often required.

The underwater parts of ships often require cathodic protection. Therefore, the paint used for the underwater parts of the hull needs to have good electric potential resistance and alkali resistance. Oil-based paints or oil-modified paints are prone to saponification and are not suitable below the boot topping.

From the perspective of fire safety, ships require that the paint inside the engine room and the superstructure are not easy to burn, and once it burns, it will not emit excessive smoke. Therefore, nitrocellulose paint and chlorinated rubber paint are not suitable for decorative paint in ship cabins.